1200mm Continuous PU Sandwich panel Production Line pu sandwich

line |

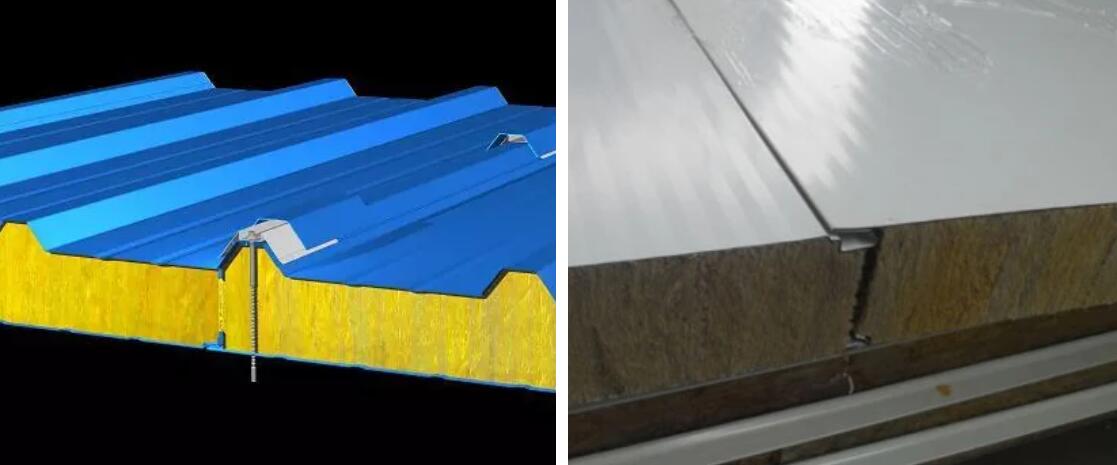

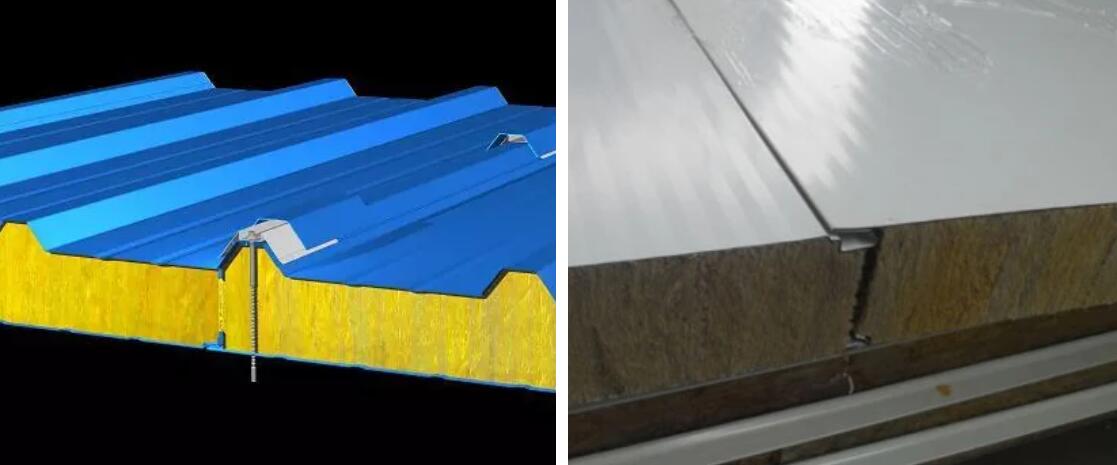

Product application of PU Sandwich Panel Production line

Due to its high efficiency and simple operation, this forming

machine is widely used in the construction of steel structure

enclosures, cold storages, and mobile buildings.

In order to satisfy various customer requirements, we design and

manufacture PU sandwich panel producton lines in different specs,

models and configurations.

Technical Data of PU Sandwich Panel Production Machine

| Min. cutting length | 3 meters | | Max. stacking length | 15m | | Panel width | 1000mm (can be designed as per client’s requirment) | | Panel thickness | Mini thickness | 40mm (corrugated sandwich panel)

50mm (wall panel) | | Max. thickness | 150mm(exclude corrugated sandwich panel) | | Steel Sheet Spec | | Thickness | 0.4-0.7mm color steel sheet | | Width | 1250mm (can be designed as per client’s requirment) | | Max. coil weight | 10 tons | | Inner Dia. of coil | 508mm | | Whole Line Spec | | Working speed | About 3-7m/min (adjustable) | | Total length | about 105m | | Working height | 1200mm (height of panel coming out) | | Pressure for foaming | 150-200 bar | | Double belt conveyor | 23m | | Control mode | Mitsubishi PLC and converter | | Total power | About 100Kw (as per final designing) | | Power required | 380V/3phase/50Hz or as per customer's requirement. | | Air pressure | 0.7Mpa (for buyer to prepare) |

|

Competitive Advantage:

1. Designed by 15 years experienced R&D members with lifetime

seivices.

2. We are "All-in-house source" factory to ensure quality and

delivery of your machines.

3. Machine’s lifetime>15 years

4. Quick delivery: in only 5-8 weeks for urgent order .

5. Introduced Mitsubishi PLC and touch screen for machine’s control

system.

6. Have our own tool center: 12 sets of CNC machines.

7. High Pricision perofrmance: Shafts are tooled by grinding

machine for two times. Rollers are tooled by CNC machines.

8. Technician can be sent to your factory to install machines and

train your workers.

uncoiler

type of uncoiler:manual

material of coil:color coating coil

thickness of sheet:0.3~0.8mm

width of coil: 1000mm,1200mm

weight of coil:≤ 5 t

inside diameter of coil:480~520mm

apply guard film

type of apply guard film: automatic

into shearing

type of shearing: electrical shearing

driven power: 0.75 kw

edge forming machine for wall

design of profile:see drawing attached

type of forming:one layer forming

roller diameter:¢72mm

material of roller: 45 steel heat treatment

thickness of chromic plating of roller surface:0.05~0.06mm

speed of forming:0~6.0m/min synchronies with panel machine

type of synchronies:electrical synchronies

driven power: 3.0 kw

installation instruction:two parts

size of forming machine:8000×2200×2200mm

weight of forming machine:~8 t

Competitive Advantage:

1. Designed by 15 years experienced R&D members with lifetime

seivices.

2. We are "All-in-house source" factory to ensure quality and

delivery of your machines.

3. Machine’s lifetime>15 years

4. Quick delivery: in only 5-8 weeks for urgent order .

5. Introduced Mitsubishi PLC and touch screen for machine’s control

system.

6. Have our own tool center: 12 sets of CNC machines.

7. High Pricision perofrmance: Shafts are tooled by grinding

machine for two times. Rollers are tooled by CNC machines.

8. Technician can be sent to your factory to install machines and

train your workers.