Automatic Metall Slitting Line Easy Operate High Speed Slitting

Machines

Introduction:

The capacity of the middle thick steel coil slitting line is mainly

used to slit steel coils of thickness 0.6~5 mm, 1~6 mm, 2-8mm or

3~10mm. And for steel coils with width: 600~1600 mm, 800~1800mm or

800~2000mm into narrower baby coils. This steel slitter is widely

used for pro

elded pipe mill, roll forming machine, etc.

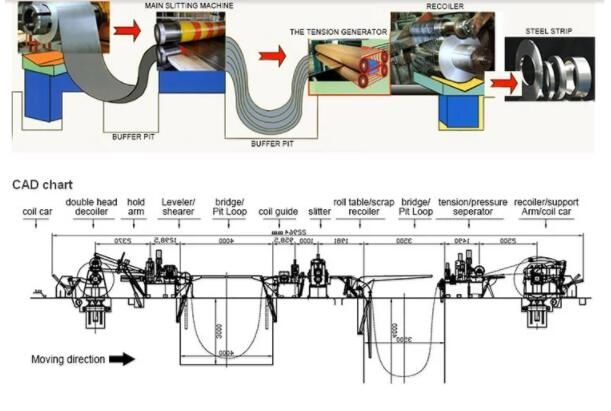

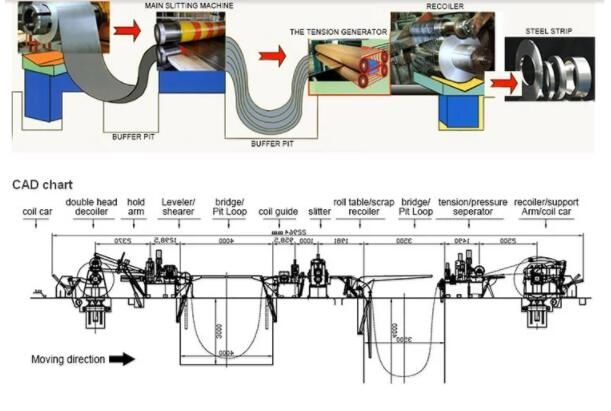

Process Flow:

Main specification:

Raw Material (if the material is stainless steel, please tell in

advance)

1). Material : carbon steel and others.

2). The thickness of the material:0.4mm-5mm.

3). Width:10mm,12mm,15mm, 20mm, 25mm, 30mm, 40mm, 50mm, 60mm.

4). Input width:600-1600mm.

Hydraulic Decoiler with car

1). The inner size:450--610mm

2). The Max width:1250mm

3). The capacity :15T 20Ton or more

Flatting and Cutting System

1). 2 shafts for feeding coil.9 shafts for flatting

2). Material of flatting:42CrMo heat treated 50-52.

3). Hydraulic system.2 sets cutting blade

4). Width of cutting:600mm--1600mm.

5). The material of blade mould:Gr12MoV

6). Power :22KW Motor with ZQ650 Reducer

Slitting syste

1). The width range :200--1300mm

2). The precious of the width:±1mm

3). The speed of slitting:25m/min

4). The width can be change.

5). Material of the slitting: Cr12MoV. Hardness of slitting

blade:HRC5860.

6). slitting:2~3mm 6 lines.

7). quantity of blades:10 sets .

8). Width of side scrap:3-15mm

9). The precious of side scrap:±0.5mm

10). Quantity of side scrap:2 strips

11). Slitting burr.

12). Power of the slitting:37KW,1000r/min,with ZQ750

Control System

1). Screen:3.2inch button screen

2). PLC:Delta

Electrical collecting machine with car

1). Material inner : 550-650mm

2). Max Coil width:1500mm

3). Carrying capacity:5T

4). Automatic relax or collect

5). Power:22KW

Product Application

Advantages & Characteristics

1. Each production line (thin sheet slitting line) is designed and

made strictly according to customer requirements. Not only this,

our engineers carefully think over in customer's shoes, making sure

whole metal coil slitter to be compact, smooth, solid and easy to

operate.

2. There are one or two hole accumulators in the middle thick coil

slitting line, which depends on minimum thickness, slitting speed,

etc factors. One pit accumulator always lies after slitter and

before tensioner.

3. According to functions & solidity request of each steel slitter

unit, we adopt suitable structure and use proper and enough

material to make each steel coil slitting line unit.

4. Good material and precise sizes of disc knives, spacers and

rubber rings on slitting shaft for our steel slitting machine can

make sure little burrs, little cambers(±0.10mm/m), no stickiness to

knives and precise slit width(+/-0.05mm).

5. Edge scrap reeler of our steel slitter uses torque motor, making

sure evenly and synchronously wind edge scraps up.

6. To change disc knives fast, double steel slitter can be chosen.

When one steel slitting machine is working, workers can install

knives on the other slitter, then just exchange locations of two

steel coil slitting line to continue work.

7. Double press rollers are installed on each equipment sequently

following each hole accumulator, in case strip head falls in hole

while feeding strip head through steel coil slitting line.

8. Coils separating & pressing-down bracket is installed on

recoiler, hydraulically driven, press on recoiling block tight and

automatically move up while recoiling diameter becomes bigger.