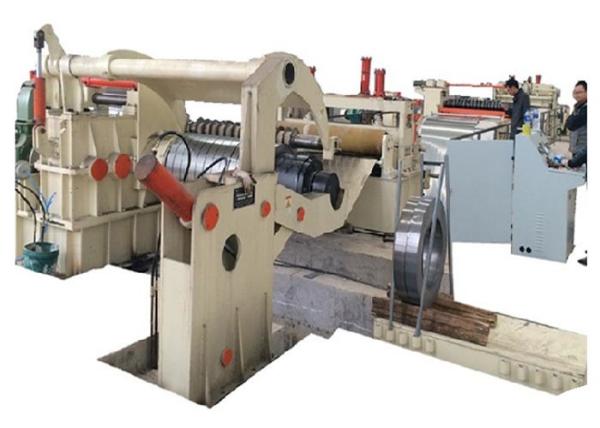

Hydraulic Aluminum Steel Coil Slitting Line Rolled Steel Sheet

Slitting Machine

Introduction of the slitting line

slitting line machine not only for the steel serivice cutting

industry, but also for the pipe industry. A lot of customers make

the pipes before slitting the large coil to the small size of

coils.

Slitting line can do uncoiling, slitting and recoiling works, make

coil steel to any needed width coil steel. It mainly includes coil

car, uncoiler, coil guide, slitting machine, scrap winder, tension

unit, recoiler and coil car, hydraulic system, Etc. It mainly used

in coil or hot rolling carbon steel, silicon steel and all the

other kinds of metal materials with surface spreading.

This line can be adjusted to do recoiling or dividing work to meet

customer’s demand.

Technical data of steel corrgated roll forming machine

| Suitable material | color steel sheet;0.3-0.7mm, |

| Working speed | about10-16m/min |

| stress | 235MPa,345MPa,550MPa. |

| Power | Main motor power: 3 Kw(Depend on final design) |

| Hydraulic station power: 7.5Kw(Depend on final design) |

| Material of forming rollers | No.45 steel, plated with chrome on surface. |

| Material of cutter,pressing die | Cr12 mould steel with quench treatment, HRC58-60 |

| Material of shaft | High quality 45# steel, Roller grinder milling. |

| Shaft diameter | 72mm |

| Controlling system | Mitsubishi PLC & converter |

| Total weight of machine | About 9500KGS |

| Machine’s size | about 18m×1.8m× 1.5m (Depend on final design) |

Machine parts in the working line

1. coil car

2. decoiler

3. peeler entry table

4. Straightener.

5. Shearing machine

6. loop table

7. coil guide and pinch roll

8. Slitting machine

9. scrap winder (both sides)

10. Loop table

11. separator and tension table

12. Deflector roll and exit threading table

13. Recoiler

14. Over arm separator in the recoiler.

15. Exit coil car for recoiler

16. Hydraulic system

17. pneumatic system

18. electrical control system

Function:

Steel coil slitting line called slitting machine which is used to

slit the big coil into small coils by doing the longitudinal

shearing for the steel coils.

Composed device:

1. Decoiler

** The motor will drive it running and help the decoiler to feed

the material to the next device

** It can expand and shrink to meet the different coil Inner

diameter's requirement.

** It is one of the important part of the slitting line

** Capacity: 5T

2. Slitter

** At the entry part, it is equipped with the side guide device to

prevent the sheets not directly go into the slitter

** Steel slitting line' s slitter part designed with the bracket

movable structure to make it easy to adjust the slit width

** It should be equipped with the blades, shim , bakelite plates or

the rubber band to make the slitting possible

3. Scrap winder

** In the slitting line it is designed to receive the waste

materials on both sides

** And a shaft with the 5.5 KW motor to wind the material with

speed adjustment

4. Tension stand

** Two shafts will be equipped with spacers to divid the strips one

by one

** The press device with felted woolen will create the first

tension part to ensure the tight and even recoiling quality

** The press part is adjustable as per the various thickness

requirements

5. Recoiler

** the press arm will divide the strips one by one and create the

tension with the tension stand

** The motor makes the speed adjustable

** Recoiler is the most importmant part of the whole steel slitting

line.

Layout of the whole line

Decoiler----Pit 1------Slitter-----Scrap WInder------Pit

2------Tension stand------Recoiler