High-speed slitting line sheet metal slitter machine slitter line

slitting

Product Advantage

The slitting process is an industry which needs qualified machine

and experienced technology link together to produce the products,

that means the machine and experience are both important, our

company are only slitting machine manufacturers who use

self-machine to produce slitting coiler in large quantity, we are

improving our machine with running them to get experienced

technology. Choose us, you do not only get the machine from us, but

you also get he experienced technology from us.

Technical data

1. The shaft of pre-depiler: Φ95×2100mm

2. Dimension and material of pre-depiler: Φ200×3mm,65Mn quenched

3. Pre-depiler installing: Push one side of torii stand

4. Damping style: Torii stand beam compress, add wood and wool felt

between the upper beam and bottom beam, add five rollers correcting

roller.

5. Pressing power: Hydraulic cylinder Φ80×150mm two pcs,

adjustable.

6. The material of five rollers correcting roller: 40Cr forged

steel,quenched hardness HRC52-55°

7. The dimension of the Straighten roller:Φ200×2150mm

8. Recoiler,press and Subsection:

9. Structure and style:Gearbox drive,Hydraulic cylinder drive to

angle sliding expansion and pinch

10. Dimension of recoiler shaft: Φ280×2100mm

11. Recoiler lump size: Φ610×2100mm

12. Expansion power: Cylinder size Φ200×100mm

13. Support bracket of recoiler shaft: Steel structure;Hydraulic

cylinder Φ80×350mm

14. Press and Subsection shaft size: Φ95×2100mm

15. Subsection size and material: Φ200×3mm,65Mn quenched

16. Depress power of subsection: Hydraulic cylinder Φ80×350mm,

adjustable

17. Cylinder size of pusher arm: Φ80×2100mm

18. Recoiling power: 160KW DC moto

19. Motor control: EUROTHERM 590 controller

20. Recoiling speed: 0~70m/min adjustable

21. Capacity of recoiling: 20000Kg

22. Unloading car:

23. Structure and style: welded steel structure with four wheels

24. Driving power: Hydraulic motor BM3-395.

25. Lifting power:Hydraulic cylinder Φ220×700mm

26. Capacity:20000Kg

27. Hydraulic station,control valve,One set Oil pipeline,pressure

16Mpa,Power:11KW-4

28. Oil tank capacity:450L

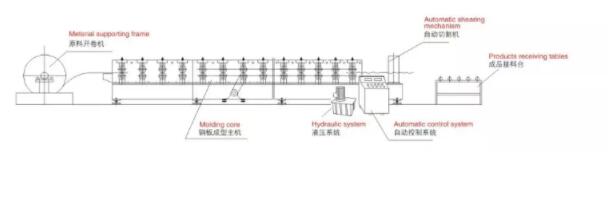

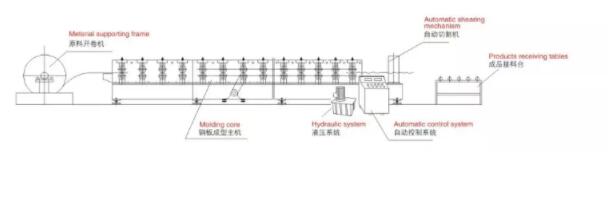

Components of the line

| Device name | Model&specification | number |

| Coil car | 32t | 1set |

| Duplex decoiler | Φ508×2000mm | 1set |

| guider, shoveller | 2000mm | 1set |

| Roller feeding, five rollers straighten | 2000mm | 1set |

| shearing machine | 2000mm | 1set |

| Correcting machine | 2000mm | 1set |

| Slitting machine | 0.5~6×2000mm | 1set |

| Cutting drive | DC.132kw | 1set |

| Scrap machine | 2000mm | 1set |

| Loop transfer bridge | 4500/2mm | 1set |

| Tension machine | 2000mm | 1set |

| coiler,arm | 610×2000mm | 1set |

| Coil drive | DC.160kw | 1set |

| Feeding car | 32t | 1set |

| electric control cabinet | DC.132kw, DC.160kw | 1set |

| Control table | Primary operation cabinet,vice operation cabinet | 2set |

| Hydraulic station | 16Mpa/450L/11kw | 1set |

| Hydraulic pipes and accessories | | 1set |

| Disk cutter | D380×d250×T15mm | 20pieces |

| Cutter shim | D300×d250mm | 335pieces |

| Rubber ring | | 180pieces |

| Division shim | D250×d95×T3mm | 40pieces |

| Separate pads | D125×d95mm | 225pieces |

| industrial felt | Thickness 16mm | 4㎡ |

Working flow

Loading coil — uncoiler — straightening head & pinching & leveling

machine — hydraulic shearing machine — vertical roll— rotary

slitting machine —scrap winder — accumulator — tension device —

recoiling machine — discharging car

Features

1. Slitting line for cutting narrow coils from main coils. For

widths of up to 3000 mm, thicknesses of up to 25 mm and speeds of

up to 160 m/min.

2. The lines are composed of high-precision slitters with quick

tooling change for slitter, tensioning device and recoiler.

High-capacity recoilers .

3. Extraction from coils without banding. Scrap ballers or scrap

choppers. Moving tensioning devices with incorporated levelling.

4. Totally computer-controlled with diagnosis, automatic coil feed

and quality control.

5. For carbon steel, exposed and non exposed materials , stainless

steel, pre-painted steel, aluminium and other metals.

Pre-sales

1. collect all requests

2. feedback asap

3. offer proper specifications

4. factory inspection available

After-sales

1. operator training free of charge

2. 12 months warranty

3. supplier offer service and units free of charge for not manual

caused damage within warranty

4. response within 12 hours by phone or video

Packing&Delivery