Reliable Automatic Metal Slitting Line 1250mm Steel Coil Sheet

Metal Slitter

Description

Steel Slitting Machine Line is composed of uncoiler, pinch &

feeder, slitter, re-coiler etc. Its function is to slit wide coils

to narrow strips coil ,which can be used for milling ,welding tube,

cold bend forming etc .at the same time changing different material

blade can slit various metal coils.

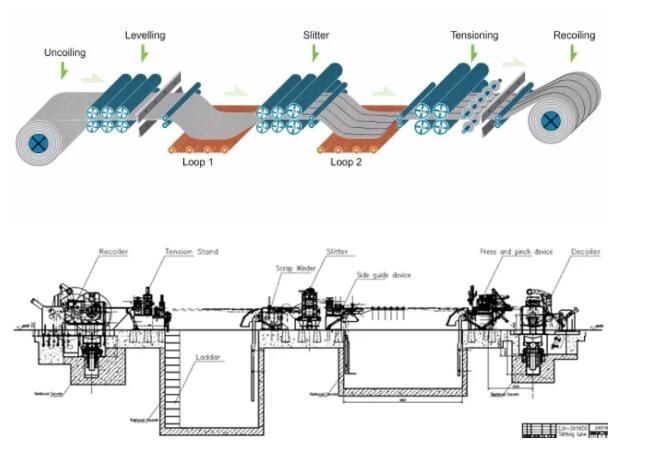

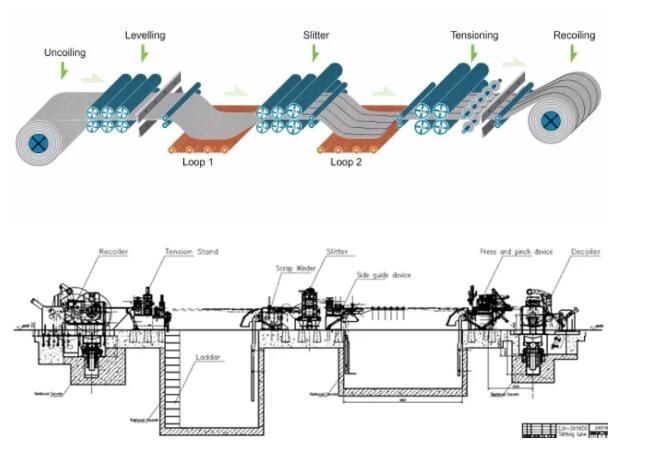

Working flow

Loading coil — uncoiler — straightening head & pinching & leveling

machine — hydraulic shearing machine — vertical roll— rotary

slitting machine —scrap winder — accumulator — tension device —

recoiling machine — discharging car

Specifications

| Model | GWC1250-3mm aluminum coil | Note |

| Applicable material | Cold rolled sheet, color plate, pickled plate and galvanized plate | This machine is customizable upon each customer's requirements and

the characteristics of processed material. |

| Feeding width | 1250mm |

| Processing thickness | 1.0mm - 3.0mm |

| Blade material | 6CrW2Si, HRC58°-60° |

| Main motor power / hydraulic station power | Z4-180-41-55kW DC motor | These parameters can be set according to the required production

capacity. |

| Forming passes | 18 |

| Forming speed | 0-80 meters/minute |

| Machine dimensions | 26×7×1.5m |

| Machine weight | 30T |

|

This Metal Slitting Line of several parts, as listed below.

1. Hydraulic loading car

2. Dual-head decoiler

3. Coil head drawing machine

4. Clamp-feeding and leveling machine

5. Cross cut shear for panel head

6. Loop bridge

7. Side stop device

8. Main slitting machine

9. Scrap baller

10. Transmission parts

11. Separator

12. Damp tensioning device

13. Main hydraulic recoiler

14. Hydraulic unloading car

15. Hydraulic system

16. Electrical control system

Advantages

1.This production line can be automatic running by input the

products length and batches to the PLC control system .

2. Very strong base frame treated to avoid any vibration.

3. Precise- All the rollers are CNC lathe processed and polished on

the surface to guarantee the accuracy.

4. All the rollers are quenched and harden treated to guarantee the

long life.

5. What’s more we also can design steel plate cut to lengh machine

according to customer’s different thickness.

Our Services

1. We will send the engineer for the installation and training of

your workers on how to operate this machine in the correct way.

2. Warranty Team

One year quality guarantee, life guarantee repair. Within the

quality guarantee period, except for failures caused by human

error, repair parts will be provided for free. After the quality

guarantee period, only charge the cost of the spare parts.

3. We supply the pre-sell and after-sell service.

pre-sell service: workshop design, and production output design

after-sell service: installation and training, and the skilled

engineer for working.

4. We can also be sent the engineer working for you serval months

or 1 year. The engineer will help you to improve the output, reduce

the waste and decrease the cost.

5. We supply the pre-sell service-Design for the whole project for

stainless steel pipe making/ carbon steel pipe making.

6. We will be responsible for loading and shipping.