0.7 - 1.2mm Metal Door Frame Roll Forming Machine Material 12 - 18m

/ min

This machine is easy to operate, low maintenance cost, and can save

us materials. It works stablly without loud noise. Forming speed

can reach 12-18m / min which saves a lot of time during work so

it's efficient. And the products it made are widely used in houses, buildings, warehouses and so on. Machine has

high grade quality and good price throughout the world since our

company was established.

Technical Parameters:

Working Material

| Galvanized Sheet(Gi),Cold Roll Steel(CRC),Hot Roll |

Thickness

| 0.7-1.2mm |

Forming Station

| 16 steps |

Cutter Material

| Cr12 Tool Steel |

Side Wall Thickness

| 18mm |

Shaft

| 65mm |

Diemension |

3000*800*1400mm |

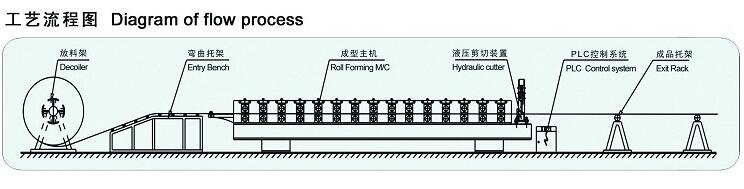

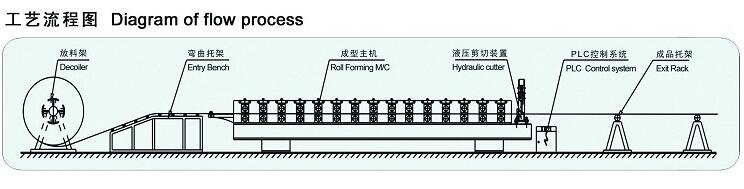

| Machine composition | Quantity | Detailed information |

| 3T Hydraulic decoiler | 1 set | Hydraulic system to expand coil inner hole; Pump motor: 3.0KW Frequency Inverter to regulate turn speed; Motor:5.5KW Coil diameter=500,510mm. Load Capacity: Max. 3T; Coil Width Max. 1250mm |

| Hydraulic Pre-cutting Device | 1 set | Smart cut control, to cut off the end of the final plece of sheet

only |

| Cold Rolling Mills | 1 set | Feeding section with guide Wall-plate-frame design Gear/Sprocket driving; 16 step to form Rollers manufactured from 45# steel, CNC lathes, hard Chrome Coated Shafts Diameter=75mm, Precision Machined Main motor=15 WX2, Max. speed of roll former:max. 12-18m/min |

| Hydraulic cutting device | 1 set | Cutting tool material: Cr12, heat treatment; mould steel with

quenched treatment Hydraulic unit, Pump motor=5.5KW /as you require |

| PLC Control System | 1 set | Combined with PLC, Inverter(Delta), Touch Screen(Weinview),

Encoder(Omron) Cut to length tolerance≤±1mm Control voltage 24V/as you require |

| Exit rack | 1 set | 4 meters long, un-powered/as you require |

Related details abt the machine:

Material Thickness:0.7-1.2mm . Applicable material:Galvanized Steel

Coils, Cold Rolled Coils, yield strength 245Mpa or 300Mpa. For decoiler, we can provide the machine according to customer's

requirements of manual or hudraulic.

Rollers manufactured from GCr15, precision machined, hard Chrome

Coated

Motor Driving,Gear chain transmission, 16 forming stations

PLC Control System(Touch screen brand:Taiwan WEINVIEW, Inverter

brand:Finland VOCAN/Denmark

Control the quantity and cutting length automatically

Combined with: PLC, Inverter, Touch Screen, Encoder, etc

Cut-to-length tolerance≤±1mm

Control Voltage 24V

After-sale service:

1 . Installation and training of roof forming machine:

a . If buyers visit our factory and check the machine, we will

teach you how to install and use the machine, and also train your

workers/technician face to face.

b . Without visiting, we will send you user manual and video to

teach you to install and operate.

c . If buyer needs our technician to go to your local factory,

please arrange board and lodging and other necessary things.

2 . After Service of roof forming machine:

a . One year guarantee for whole roof forming machine.

b . 24 hours technical support by email or calling

c . If there is any problem found of the roof forming machine, we

will repair it for free in one year.