Wuxi YBT machinery Equipment co.,ltd established in 1998,

specialize in cold roll forming machine and auto-producing line.To

put customers'benefit on the first, we know our success comes from

customers'success and support. We run this mind through the whole

process from the design and develpment to after-sale service in

order to help our customer increase efficiency and reduce cost to

strengthen competitive forces. Our designer and sales will listen

to your reuirement to help you receive an ideal equipment.Our

company has perfect internte for after-sale service which can

support the after-sales so that you can get the satisfied

equipment, ensure you receive our considerate service by solving

all the problems which appeared during using the machine.

We will do the best machine to my all customers!

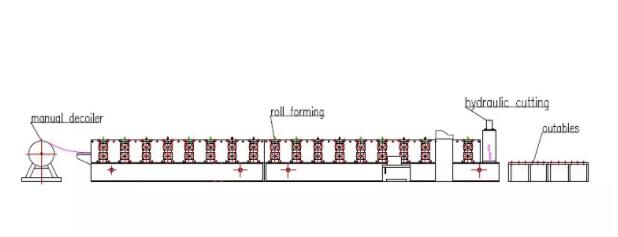

Our roll forming machine series:

1. Steel Silo Roll Forming Machine

2. Shutter Door Roll Forming Machine

3. C Z Purlin Roll Forming Machine

4. PU Sandwich Panel Line

5. Rock Wool Production Line

6. Highway Guardrail Roll Forming Machine

7. Floor Deck Roll Forming Machine

8. Cable Tray Roll Forming Machine

9. Steel Roll Forming Machine

10. Metal Slitting Line

11. Cut To Length Line Machine

12. Downpipe Roll Forming Machine

13. H Beam Welding Line

We will try do our best for make best quality machine!